Description

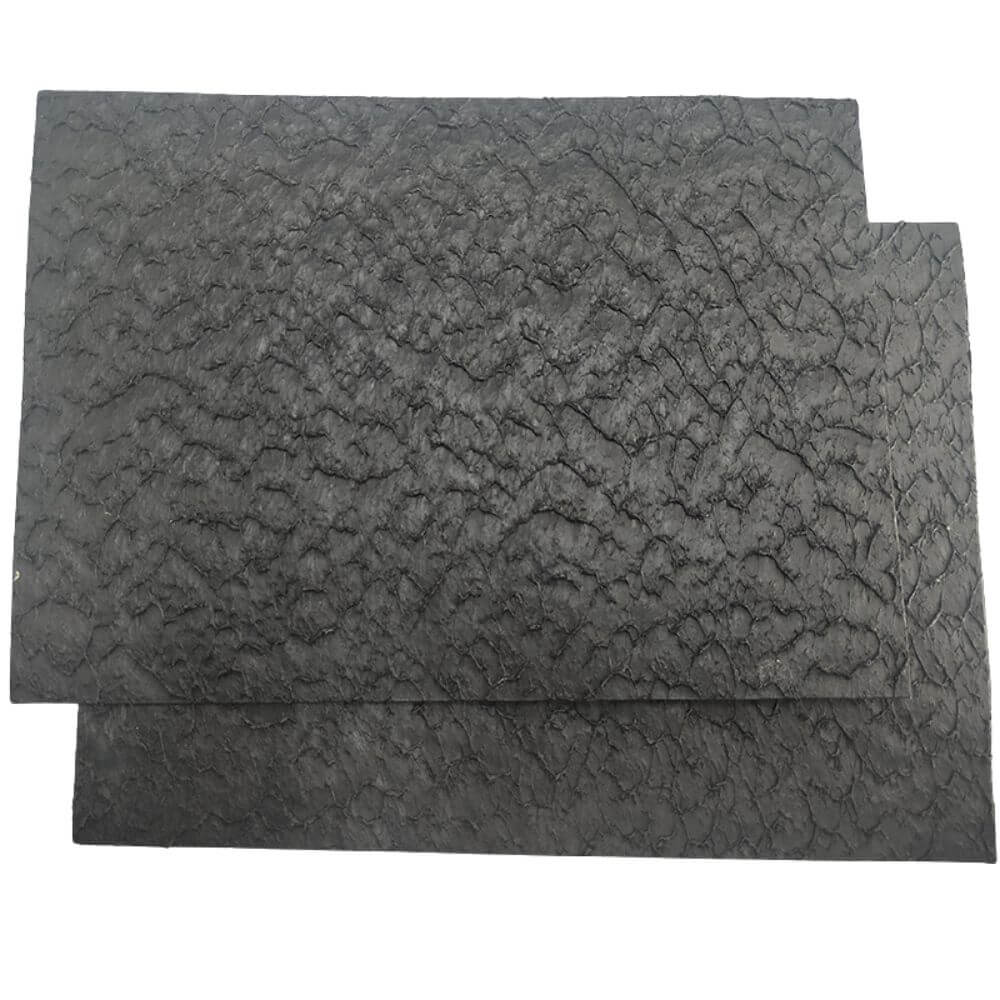

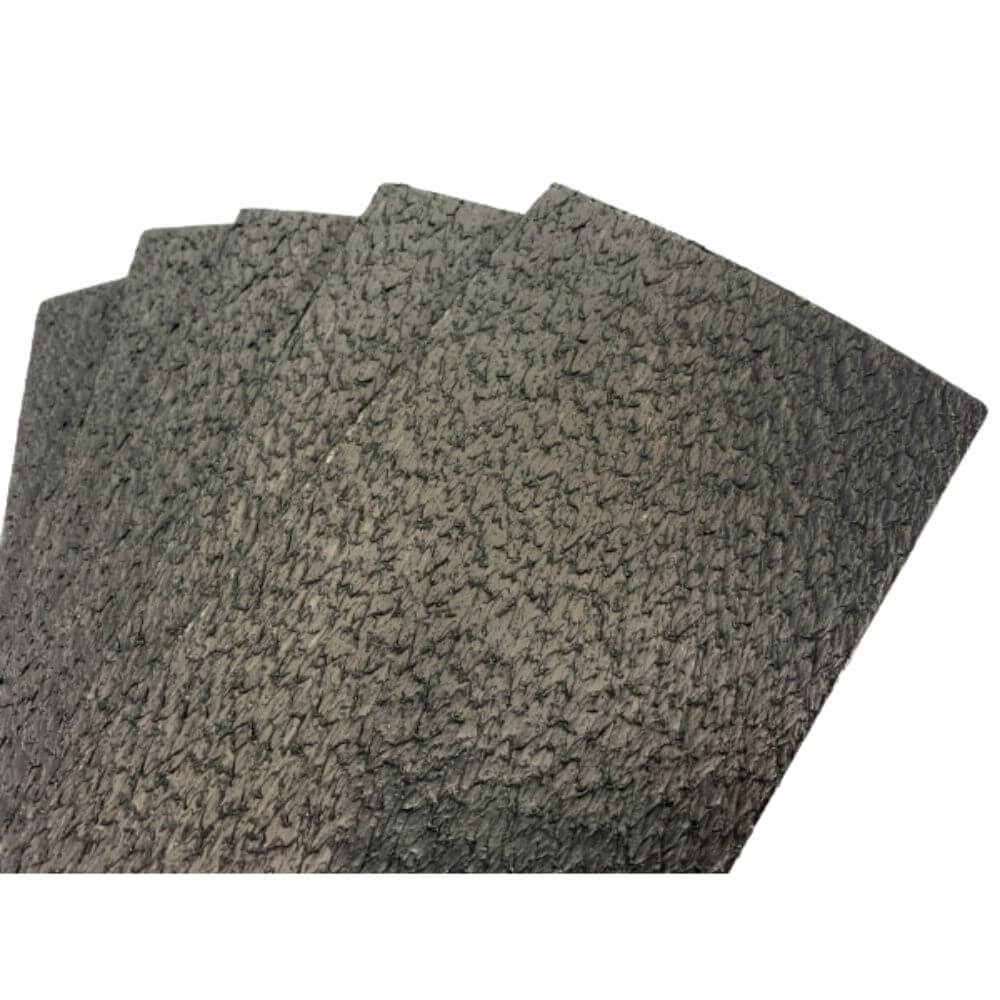

Xinyu Geosynthetics textured hdpe geomembranes are engineered to deliver optimum performance in difficult geotechnical and environmental applications. Our liquid-tight liners consist of high-strength, high-density polyethylene (HDPE) with a textured surface for greater friction and stability, making it ideally suited to difficult applications.

(Source: https://youtu.be/70x-yM3oeMY)

Specfications of Textured HDPE Geomembrane

Properties | Unit | Standard | Test Frequency | Minimum Average Roll Value | |||

Thickness | mm | D5994 | Per Roll | 1.00 | 1.50 | 2.00 | 2.50 |

Asperity Height | mm | D7446 | Every 2nd Roll (2) | 0.25 | |||

Density | g/cc | D1505/D792 | 90,000 kg | 0.94 | |||

Tensile Properties | |||||||

Yield Strength | KN/m | D6693 Type IV | 9,000 kg | 15 | 22 | 29 | 37 |

Break Strength | KN/m | 9,000 kg | 10 | 16 | 21 | 26 | |

Yield Elongation | % | 9,000 kg | 12 | 12 | 12 | 12 | |

Break Elongation | % | 9,000 kg | 100 | 100 | 100 | 100 | |

Tear Resistance | N | D1004 | 20,000 kg | 125 | 187 | 249 | 311 |

Puncture Resistance | N | D4883 | 20,000 kg | 267 | 400 | 534 | 667 |

Stress Crack Resistance | Hour | D5397 | per GRI GM-10 | 300 Hours | |||

Carbon Black Content | % | D4218 | 9000kg | 2.0%-3.0% | |||

Carbon Black Dispersion | D5596 | 20,000 kg | For 10 Different Views: 9 in Categories 1 or 2 and 1 in Category 3 | ||||

Oxidative Induction Time | |||||||

Standard OIT | Min | D3895 | 90,000 kg | 100 Min | |||

High-Pressure OIT | Min | D5885 | 90,000 kg | 400 Min | |||

Oven Aging at 85°C Retained After 90 Days | % | D5721 | Per Each Formulation | 55% | |||

Standard OIT | D3895 | Per Each Formulation | 80% | ||||

High-Pressure OIT | D5885 | Per Each Formulation | 80% | ||||

UV Resistance | |||||||

High-Pressure OIT – % Retained After 1600 hrs | % | D5885 | Per Each Formulation | 50% |

Dimensions and Packaging of Textured HDPE Geomembrane

Thickness(mm) | Roll Measurement(m) |

0.5 | 7*420 |

0.75 | 7*280 |

1.0 | 7*210 |

1.25 | 7*168 |

1.5 | 7*140 |

2.0 | 7*105 |

2.5 | 7*84 |

3.0 | 7*70 |

Item Type | HDPE Geomembranes | LLDPE Geomembranes | PVC Geomembranes | EVA Geomembranes |

20ft. Container | 10-12 Rolls | 12-14 Rolls | 14-16 Rolls | 12-14 Rolls |

40ft. Container | 20-24 Rolls | 24-28 Rolls | 28-32 Rolls | 24-28 Rolls |

20ft. Container | 5000-7200㎡ | 6000-8400㎡ | 4500-6000㎡ | 5000-7200㎡ |

40ft. Container | 10000-14400㎡ | 12000-16800㎡ | 9000-12000㎡ | 10000-14000㎡ |

Weight Per Roll | 500-1500kg | 400-1200kg | 300-900kg | 400-1000kg |

Roll Width | 6-8m | 5-7m | 2-6m | 4-6m |

Roll Length | 50-100m | 50-100m | 50-100m | 50-100m |

Real Case of Textured HDPE Geomembrane Applying in Landfills Expansion Field

Project Name: Kuala Lumpur Municipal Landfill Expansion Project, Malaysia

Use Textured HDPE Geomembrane In the Landfill Expansion Project

Textured HDPE Geomembrane Applied in a Landfill Expansion Project of Malaysia

Overview:

Xinyu Geosynthetics, a waste management authority in both China and Malaysia, worked together to supply higher Textured HDPE Geomembranes specially made for slope reinforcement and leachate control to the Kuala Lumpur Municipal Landfill Expansion Project. The objective of this initiative was to ensure that the slope was stable and that there was no leachate infiltration into the urban dump that was growing rapidly. The highlight of the whole project was our Textured HDPE Geomembrane, which showed superb friction as well as durability and received enthusiastic feedback from the local engineers who were impressed greatly with its performance in the tropical conditions of Malaysia.

Challenges:

- Severe angles caused by forces to apply high friction to avert liner sliding.

- Substantial precipitations and moisture requiring shielding from tough materials that are weather-proof.

- Forming the new landfill in Kuala Lumpur to address the growth of its waste was very urgent.

Solution:

The 1.5mm Textured HDPE Geomembrane, as a main product of this geosynthetic system, was already designed for the use in steep slopes and impermeability. After customers placed their orders, the samples were sent to a third-party lab in Singapore for testing. As a result, these samples were proved to reach the GRI GM13 standards while recognized by our local clients at the same time. The table below gives more details on the products used:

Product | Specification | Quantity |

Textured HDPE Geomembrane | 1.5mm Thickness, Double-sided | 385,600 m² |

Smooth HDPE Geomembrane | 1.5mm Thickness | 128,300 m² |

Long Fiber PET Filament Non-Woven Geotextile | 350 g/m² | 642,800 m² |

Long Fiber PET Filament Non-Woven Geotextile | 200 g/m² | 22,500 m² |

Implementation:

Covering 385,600 m², our 1.5 mm Textured HDPE Geomembranes were deployed on the steep slopes as well as the vertical sections of the landfill. Due to its two-sided textured surface design with the help of co-extrusion calendering, they are able to withstand the roughest weather. The flatter areas were lined by the Smooth HDPE Geomembrane (128,300 m²), while the non-woven geotextiles (350 g/m² and 200 g/m²) were used for boosting drainage and filtration. Filling a 22-day delivery requirement, Xinyu Geosynthetics got all its production in gear and was able to deliver the containers – five of them were sent off earlier, and the rest punctually, by the time the deadline was up.

Support On-Site:

Our technicians were on-site Kuala Lumpur group to assist with the welding process and installation work. With our 12+ years of experience, the Textured HDPE Geomembrane we had installed successfully optimize the gripping of textured surface, which in return brought simplicity to the slope installation and guaranteed its long-term reliability.

Project Results:

- Slope Stability Achieved: The textured surface was a preventive of slipping off and hence it was never reported any incident of the landfill’s steep terrain after 12 months.

- Leak-Proof Performance: The system successfully managed leachate which then met the environmental standards in Malaysia and preserved the quality of groundwater.

- Client Feedback: The project engineers favored the friction-increasing design of Xinyu Geosynthetics for the Textured HDPE Geomembrane and were convinced by the fact that we were of quality service and, at the same time, prompt in helping them.

Project Memo Conclusion

The project goes to show how strong Xinyu Geosynthetics’ Textured HDPE Geomembrane really is. It was designed and made for the steep slope application, including its high friction, durability, and the fact that it can be easily and quickly installed. It was an on-demand choice of the technology which is both environmentally friendly and of high engineering quality.

Key Features and Benefits of Textured HDPE Geomembrane

- Textured for Enhanced Friction: Our geomembranes are single-sided or double-sided textured. With raised surface patterns, this textured geomembrane comply with ASTM D7466 requirements for roughness while can enhance the friction coefficient for better anti-slip on steep slopes and vertical walls.

- Unrivaled Long Lasting Life: Coupled with carbon black, UV stabilizers, anti-aging fillers, and stabilizers, these liners provide greater resistance to UV radiation, chemicals, punctures, stress cracking induced by the environment, and high temperatures.

- Higher Engineering Stability: Compared with smooth hdpe geomembranes, the rough texture can enhance the angle of friction. In this case, textured hdpe geomembrane can ensure the stable performance under hostile conditions such as landfills, dams, and mines.

- Seamless Installation: Our geomembranes utilize smooth edge preparation for high-quality thermal fusion welding, with leak-free, safe seams between sheets for maximum project efficiency and volume.

- Economical Anti-Seepage: Textured HDPE Geomembranes provide long-term impermeability at low expense with greater performance than other materials such as LLDPE through better flexibility and specific strength.

Varied Applications of Textured HDPE Geomembranes

Textured HDPE Geomembranes have several advantages over many applications and projects in different industries, including:

- Environmental Landfills: Preventing leachate leakage and protecting groundwater.

- Mining & Tailings Management: Slope stabilization and containment of highly aggressive chemicals.

- Water Conservancy: Lining reservoirs, canals, and sewage ponds for leak-proof storage.

- Municipal & Chemical Projects: Providing durable, safe urban and industrial applications barriers.

- Steep Slope Engineering: Enhancing embankment, dam, and vertical structure stability.

Why Wholesale and Use Textured HDPE Geomembranes From Xinyu?

Manufactured through high-technology co-extrusion calendering processes, our textured hdpe liners are comparable to or exceed GRI GM13 standards, ensuring you of high-quality material. With a single-side texture for medium slopes and double-side texture for severe applications, we offer bespoke solutions to enable you to derive an optimum out of your project. Their weldability, weathering, and aging resistance ensure you of long-term performance even under severe conditions.

Ready to Get Started? Breathe life into your project with Textured HDPE Geomembrane strength and reliability. Contact us today for a free quotation and technical data or to talk about bespoke solutions to fit your needs.

Reviews

There are no reviews yet.