Description

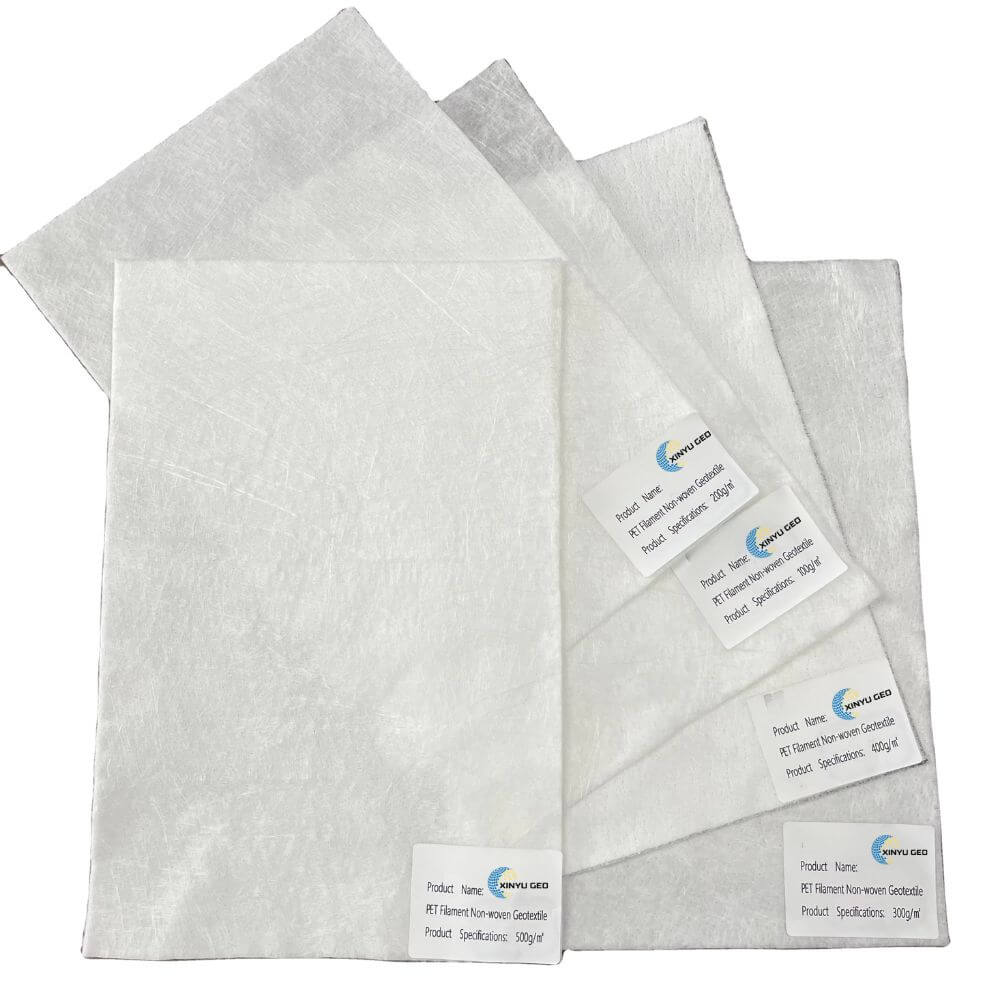

Polyester(PET) Filament Non Woven Geotextile Fabric

At Xinyu Geosynthetics, we’ve mastered the production of Polyester (PET) Filament Non Woven Geotextiles for over a decade. Manufactured from virgin polyester by needle-punching and thermal bonding, our geotextiles provide first-rate strength, durability, and drainage for civil engineering applications across the globe. Featuring a 3D fiber structure, they’re designed to reinforce, filter, and protect under even the most challenging conditions. Browse our product below and discover why Xinyu is a name you can rely on.

Specfications of PET Filament Non Woven Geotextiles

Data | Test Method | Unit | XY10 | XY15 | XY20 | XY25 | XY30 | XY35 | XY40 | XY45 | XY50 | XY60 |

Ultimate Tensile Strength, MD | ASTM D4595 | KN/m | 7 | 11 | 14 | 17 | 19 | 24 | 27 | 30 | 37 | 41 |

Ultimate Tensile Strength, TD | ASTM D4595 | KN/m | 6 | 10 | 12 | 15 | 17 | 21 | 25 | 28 | 34 | 38 |

Tensile Elongation | ASTM D4595 | % | 45 | 45 | 50 | 50 | 50 | 60 | 60 | 60 | 60 | 60 |

Grab Tensile Strength, MD | ASTM D4632 | N | 400 | 600 | 850 | 1000 | 1250 | 1450 | 1700 | 1900 | 2100 | 2500 |

Grab Tensile Strength, TD | ASTM D4632 | N | 350 | 550 | 700 | 900 | 1100 | 1250 | 1450 | 1600 | 1800 | 2150 |

Grab Elongation | ASTM D4632 | % | 45 | 45 | 50 | 50 | 50 | 60 | 60 | 60 | 60 | 60 |

Trapezoid Tear Strength, MD | ASTM D4533 | N | 160 | 300 | 350 | 430 | 490 | 540 | 630 | 710 | 770 | 920 |

Trapezoid Tear Strength, TD | ASTM D4533 | N | 140 | 270 | 330 | 400 | 450 | 510 | 610 | 690 | 750 | 900 |

CBR Puncture Strength | ASTM D6241 | N | 1000 | 1800 | 2300 | 2700 | 3200 | 3600 | 4400 | 4800 | 5800 | 6900 |

Apparent Opening Size O90 | ASTM D4751 | mm | 0.12 | 0.11 | 0.11 | 0.10 | 0.09 | 0.09 | 0.08 | 0.08 | 0.08 | 0.08 |

Water Flow Q100 | ASTM D4491 | L/m2/s | 250 | 235 | 220 | 200 | 185 | 165 | 125 | 110 | 90 | 80 |

Weight | ASTM D5261 | g/㎡ | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 |

Thickness | ASTM D5199 | mm | 1.2 | 1.8 | 2.3 | 2.9 | 3.2 | 3.6 | 3.9 | 4.2 | 4.4 | 4.8 |

Dimensions and Packaging of PET Filament Non Woven Geotextiles

Thickness(mm) | Roll Measurement(m) |

1.8 | 6*200 |

2.3 | 6*150 |

2.9 | 6*100 |

3.2 | 6*100 |

3.6 | 6*100 |

3.9 | 6*80 |

4.2 | 6*80 |

4.4 | 6*50 |

4.8 | 6*50 |

Item Type | PET Filament Nonwoven Geotextiles | PET Staple Fiber Needle Punched Nonwoven Geotextiles | PP Staple Fiber Needle Punched Nonwoven Geotextiles | PP Woven Geotextiles |

20ft. Container | 15 Rolls | 18 Rolls | 20 Rolls | 22 Rolls |

40ft. Container | 30 Rolls | 36 Rolls | 40 Rolls | 44 Rolls |

20ft. Container | 1200㎡ | 1440㎡ | 1600㎡ | 1760㎡ |

40ft. Container | 2400㎡ | 2880㎡ | 3200㎡ | 3520㎡ |

Weight Per Roll | 300kg | 250kg | 200kg | 150kg |

Roll Width | 4-6m | 4-6m | 4-6m | 4-6m |

Roll Length | 50m | 50m | 50m | 50m |

Why Select Xinyu Polyester Filament Non Woven Geotextile?

Our Polyester Filament Non Woven Geotextile Fabric is the most versatile and highest-performing. With long-term reinforcement, it surpasses woven equivalents in drainage and filtration. It is made to the world’s highest standards and is the project’s first choice for strength and flexibility. Why?

- Improved Strength: Superior tensile strength and puncture resistance. It can easily resist heavy construction loads.

- Long-Term Stability: Acid, alkali, and UV-stable. Anti-aging construction 10+ years of life.

- Excellent Drainage: The pores’ size range is vast, and the paths are tortuous. The material absorbs impurities while allowing water to pass through.

- Easy Installation: Light roll easily unrolls. Saves labor costs and time in construction.

- Project Boost: Extends road life and improves soil stabilization. Saves money in quality and efficiency improvement.

Applications of Polyester Filament Non Woven Geotextile Fabric

(Source-https://youtube.com/shorts/GZT6uvhiUEQ)

Xinyu’s Polyester Filament Non Woven Geotextile is one-of-a-kind and has many applications with the one-for-all concept. It’s being applied globally for:

- Road Construction: Pavement life extension and subgrade reinforcement.

- Erosion Control: Soft soil protection under slopes and embankments.

- Drainage Systems: Water filtration under playgrounds or rail ballast.

- Landfills: Soil entry prevention and material separation.

- Soil Stabilization: Weak base stabilization in airports and railways.

Polyester Filament Non Woven Geotextile Fabric Used in Road Construction in Malaysia

Client’s Problem

There was a need for a new highway in northern Malaysia to cut through soft, spongy, swampy soils overlying coastal floodplains. These soils gave the design engineers a lousy time. High water content, low strength, and poor drainage threatened sinkage or cracking of roads without a system of reinforcement. The contractor needed a solution to stabilize the subgrade and manage water. After some digging around, they approached Xinyu Geosynthetics for help. We suggested using Polyester Filament Non Woven Geotextile Fabric, geomembrane, and drainage materials to get the job done.

Solutions From Xinyu Geosynthetics

Polyester Filament Non-Woven Geotextile Fabric is a tough, elastic fabric made of continuous polyester filaments. It’s needle-punched and thermally bonded for toughness. This geotextile stabilizes the soil, filters water, and drains water without causing erosion. Used in conjunction with geomembrane and drainage layers, it’s perfect for road construction like this.

Soft ground was the arch-nemesis of this Malaysian highway. Xinyu Geosynthetics came to the rescue with a solution. We used our geotextile to stabilize the roadbed, a geomembrane to keep water from seeping in, and drainage materials to keep it dry. Here’s what transpired.

Products Used

Product | Specification | Quantity |

PET Filament Non Woven Geotextile | 300 g/㎡, 5.8m*100m | 80,000 ㎡ |

1.0mm Thickness | 60,000 ㎡ | |

Geocomposite Drainage Net | 200 g/㎡, 4m*50m | 60,000 ㎡ |

Implementation Process

- Prep Work: The team graded the roadbed, removed obstructions and loose dirt, and spread a base of sand down first—flat and level—to ensure it was secure.

- Laying Materials: We placed the Polyester Filament Non Woven Geotextile Fabric across the subgrade. It was pinned with no wrinkles or overlaps. Then, the HDPE geomembrane went on top to stop water from passing through. Finally, the geocomposite drainage net came in to take water away.

- Fixing It Up: The entire thing was nailed down tightly. A number of rolls were spliced together perfectly for full coverage, locking stability in.

- Final Touches: Sand covered the material, which was then packed tightly. This made the roadbed stronger and shielded the layers below.

Xinyu’s geotextile is virgin polyester fiber knotted in a 3D structure by needle-punching. It’s strong, drains well, and endures long. The geomembrane added another leak-free layer, and the drainage net ensured water flowed freely. Combined, they gave a mushy mess a solid foundation.

Implementation Results

- Sturdier Roadbed: Geotextile dispersed loads and stopped sinking. Stability improved by leaps and bounds.

- Better Drainage: Water flowed through the geotextile and drainage net. There is no waterlogged soil anymore.

- Erosion Control: The geomembrane and geotextile held the soil back. Floodplain rains couldn’t wash it away.

- Increased Life Span: UV resistance and strength guaranteed this road would last. Cracks? Not on this road.

Advantages of Xinyu’s Solution

- Increased Strength: High tensile strength supported traffic loads. The roadbed was solid.

- Water Management: Fine pores filtered soil out but released water rapidly. The drainage net helped as well.

- Erosion Fighter: Soil was held in position, even with heavy rain. Slopes were stable.

- Tough Stuff: Resisted chemicals, UV radiation, and abrasion. It lasted 10+ years as planned.

- Quick Setup: Rolls and lightweight materials speeded it up. Costs stayed low.

Why Did the Client Select Xinyu Geosynthetics?

This Malaysian highway construction project allowed our Polyester Filament Non-Woven Geotextile Fabric to shine. With geomembrane and drainage material incorporated into the mix, we cut through soft soil like experts. Xinyu Geosynthetics contributed engineering know-how and best-in-class products to the mix. Roads, railways, and every type of infrastructure in between—we have solutions that perform—and save you money. Thanks to our geosynthetics, this highway’s now a stable, smooth drive.

About Xinyu Geosynthetics

Our Polyester Filament Non-Woven Geotextiles have reshaped projects in over 20 countries, from Asian highways to European landfills. With unbeatable tensile strength, drainage, and anti-aging, they’re ideal where function meets durability. Quick-deploy or custom spec, Xinyu is the solution.

Let’s Fulfill Your Solution!

Ready to make your next project long-lasting? Get a free quote, consultation, or samples of our Polyester Filament Non-Woven Geotextile. Let’s keep it simple, strong, and successful!

Reviews

There are no reviews yet.