Road construction involves serious planning, solid design, and proper execution. Whether through potholes, cracks, or other forms of premature structural failure, road failure can be costly and dangerous. Therefore, there has always been a desire among engineers and contractors to find methods of constructing longer-lived roads that will better resist environmental stress, mechanical loading, and chemical attack.

HDPE Geomembrane Liner in Modern Projects: Applications and Advantages

Over the past decades, the focus on sustainability and environmental protection has steadily been increasing on the agenda of businesses, municipalities, and agriculture around the world. Increasing awareness about pollution and scarce natural resources, along with enhanced needs for value addition in managing waste, further motivated the interest of the project owners in utilizing geosynthetics to enhance their operational efficiencies and reduce their ecological footprint. One of the most promising and reliable alternatives that has emerged nowadays is the HDPE Geomembrane Liner.

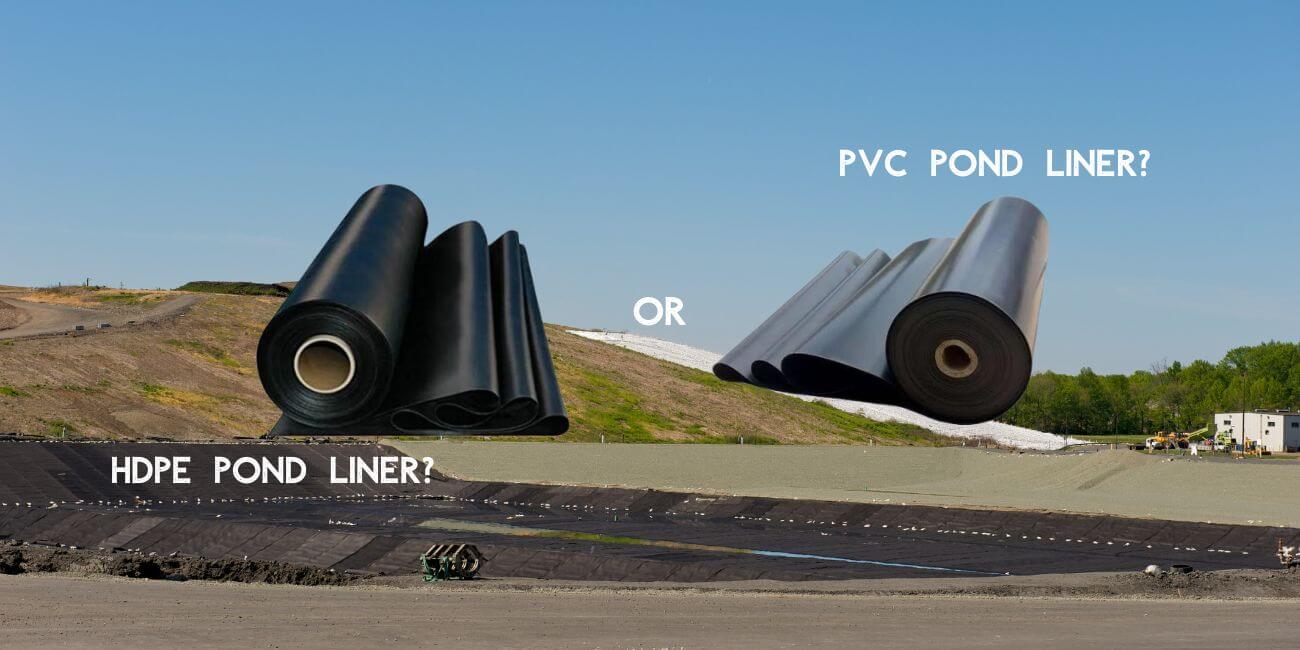

HDPE Pond Liner vs. PVC Pond Liner: Which One is Better?

Ponds have gained much popularity in recent years for their contribution to aquaculture, irrigation, recreation, and even industry. Be it to build a small backyard pond to house decorative fish or to construct a large reservoir to irrigate farmland, the right Pond Liner is called for. Besides preventing the seepage of water, the pond liner ensures that whatever is contained therein-fish, plants, or chemicals-remains therein for a long period.

Read more

What is Geosynthetic Clay Liner?

Water seepage control is one of the crucial areas in civil engineering, environmental management, and landscaping. Whether it is the artificial lake construction at a resort, lining a landfill site so that it will not contaminate the adjacent land, or protection of an underground garage from potential water damages, impervious systems become inevitable. Recently, geosynthetics have been developed to address such practical challenges in an effective way. Among such, one of the most popular is the Geosynthetic Clay Liner, or GCL, composed of natural bentonite clay combined with geotextiles.

What is a Drainage Board?

Water management around the structure remains one of the most crucial aspects of modern construction. Be it the construction of a house, a commercial building, or even a road, and also while designing a garden, one thing is for sure: unregulated water may cause several problems related to the failure of structure foundations, mold growth, soil erosion, and many more.

What is Geotextile and Its Tutorial For Use in Projects

Geotextiles have become an essential aid during the modern age of civil engineering, construction, and landscaping when trying to solve problems related to soil. Geotextiles serve very important functions, such as improving the performance of roadways, erosion prevention, and embankment stability, among others. Nevertheless, many people outside the construction or geotechnical engineering circle do not know what a geotextile is, let alone how it works.

Read more

Why Should You Import Geomembrane From Xinyu Geosynthetics?

Geomembranes find their vital application in modern times in construction, protection of the environment, and agriculture, among many uses. Be it for companies seeking trustworthy suppliers of wholesale geomembrane solutions: Xinyu Geosynthetics will be one such company. The following article will talk about why you should import and wholesale geomembrane from Xinyu Geosynthetics, which may become a strategic decision pertaining to the success and sustainability of your projects.

Important Things You Should Know About HDPE Geomembrane

Securing appropriate, durable, and green containment facilities is the key requirement in the modern aspects of civil engineering and environmental management. From wastewater storage to landfill caps and the prevention of chemical seepage into the soil from mining sites, one prevailing solution is through HDPE geomembranes. HDPE stands for High-Density Polyethylene. It is a kind of polymer liner that is so versatile, having been used in various fields and revolutionizing containment practices.

Top 10 Geomembrane Manufacturers in China 2025

It has become so intertwined with modern engineering that everything from environmental containment and waste management to aquaculture and mining finds some use. Geomembrane liners offer impermeable or near-impermeable barriers, inhibiting seepage and protecting the underlying soils and groundwater, adding much structural integrity to many projects. Many countries manufacture geomembranes; however, China has emerged as one of the biggest manufacturing hubs and offers many suppliers whose products cover a wide range of specifications.

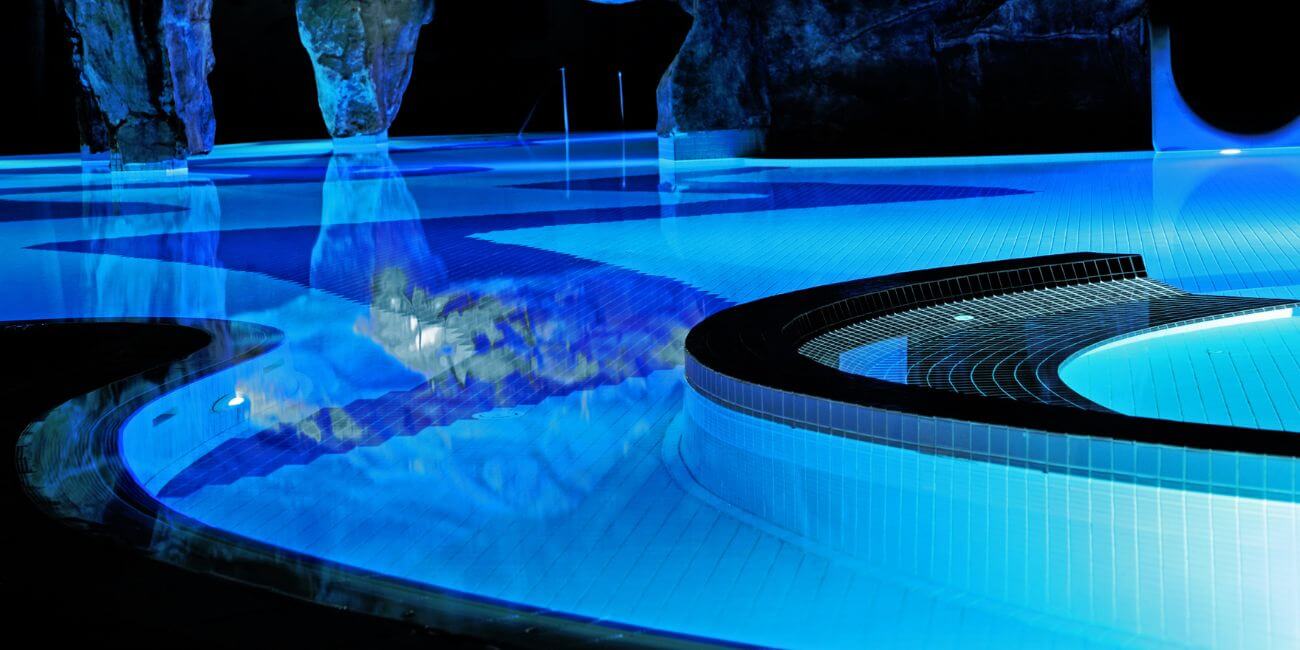

Geomembrane Liner for Above-ground Pools: Things Your Need to Know

Above-the-ground swimming pools are highly recommended mainly because they are relatively cheap to invest in and easy to install for one to swim in the backyard. Above all, a staunch liner capable of halting the evil leakage and offering quality determines its durability and strength. The best solution in the above-ground pool liners is the geomembrane liner, which is extremely strong and flexible and can be applied at many sites, especially in water retention.